The characteristics and applications of rails.

Heavy rails are made from carbon quiet steel smelted in a flat furnace and oxygen converter. Due to the large quantity required, it is necessary to import railway and railway accessories according to the physical and chemical properties required by China's technical standards and relevant foreign standards. Therefore, heavy rail manufacturers want to know more!

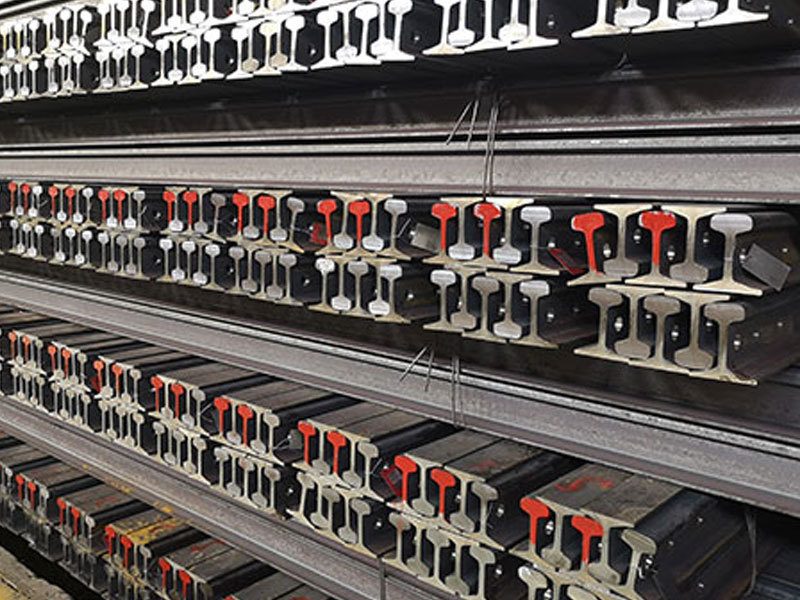

The cross-sectional shape of the lifting rail track consists of an I-shaped section with bending resistance, composed of the rail head, rail waist, and rail bottom. To ensure that the guide rail can better withstand various forces and meet the necessary strength conditions, the rail must have sufficient height, and the head and bottom must have adequate area and height, while the waist and bottom should not be too thin.

To conduct statistical analysis and assess railway damage, it is necessary to classify the damage to the railway. Based on the location of the damage, its occurrence, and the cause of the damage in the rail track section, it is divided into 9 types and 32 kinds of damage, categorized into two digits. The tens digit indicates the location and state of the damage, while the units digit indicates the cause of the damage.

Lateral wear occurs on the outer chain of small radius curves and is one of the main types of damage on curves. The friction and slipping of the rails when trains travel on curves are the fundamental causes of lateral rail grinding. When a train passes through a small radius curve, there are usually two contact points between the wheels and the track, mostly resulting in lateral grinding. The size of lateral grinding can be expressed as the product of guiding force and impact angle, known as the wear coefficient. Improving the conditions for trains passing through curves. For example, when using wear-type wheel treads, if radial trucks are used, the speed of lateral grinding will decrease.

Afterwards, the railway began to switch to iron tracks. After decades of improvement, the materials used were changed to steel, and the quality of steel has greatly improved. The steel rails used on railways must withstand significant pressure, so high-quality steel is required. The requirements for railway steel are higher than for other applications; similarly, small wounds appearing in the rebar used in buildings may not cause any issues. However, once a problem occurs with railway tracks, trains can derail at any time.

Modern steel rail cross-sections are shaped like a "工" character, divided into the rail head that contacts the wheels, the middle rail waist, and the bottom rail base. Different routes have different requirements for the strength, stability, and wear resistance of the rails. Therefore, there are also different standards for rails, and a route should select one based on economic and technical factors.

Tag:

Next Page

Next page:

recommend News

Saint Ark explains what light rail is.