The application of rails in railways.

Rails, formally known as railway tracks, are a type of railway facility. They are used on railways and work in conjunction with switches and turnouts, allowing trains to run without needing to turn. Railway tracks typically consist of two balanced rails. The rails are fixed on sleepers, with ballast underneath.

Early tracks were made by nailing thin iron plates onto wooden rails. However, these tracks had a very low load-bearing capacity, so although the construction cost was low, it was not cost-effective in the long run.

Later, railways began to use steel rails, and after decades of improvement, the materials changed to steel, with significant enhancements in quality. The steel rails used on railways must withstand immense pressure, thus requiring very high-quality steel. The requirements for steel in railway tracks are higher than in other applications. A small flaw in steel used in buildings may not cause any issues; however, the same flaw in railway tracks could lead to rail breakage and cause trains to derail. Rails are not cheap and constitute a significant part of railway costs.

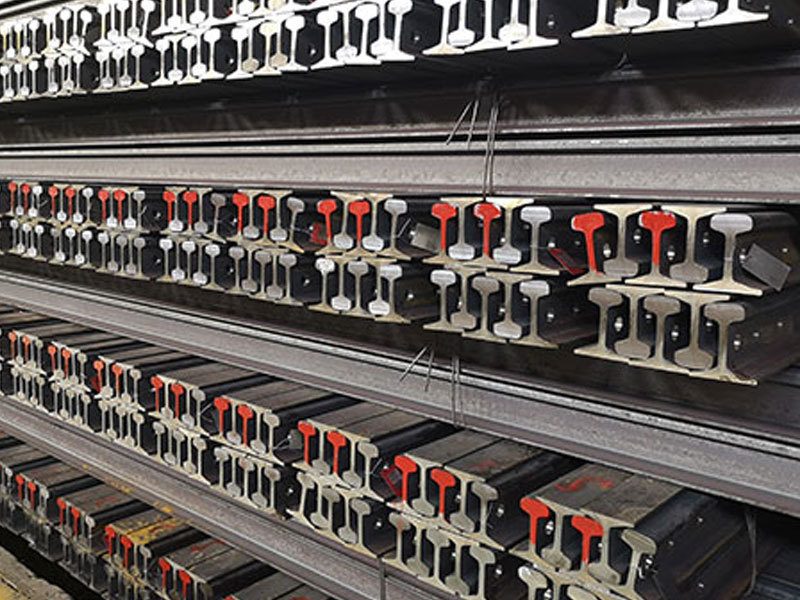

Modern steel rails have a cross-section shaped like a 'I', consisting of the rail head that contacts the wheels, the middle rail web, and the bottom rail base. Different routes have varying requirements for the strength, stability, and wear resistance of the rails. Therefore, there are different specifications for rails. The choice of which type to use on a route should consider economic and technical factors.

Tag:

Next Page

Next page:

recommend News

Saint Ark explains what light rail is.