What are the methods for dealing with rust on railway tracks? Let's popularize this knowledge from the perspective of a crane rail manufacturer.

Lifting railCan the manufacturer provide some information on how to deal with rusty rails?I think no one is unaware of train tracks. Since the late 19th century, train tracks have appeared in people's sight, and to this day, train tracks are very common in our daily lives. Especially in China, where the high-speed rail network is rapidly developing, train tracks can be seen in the suburbs. Moreover, pendulum photography is very popular now, and many people choose to do pendulum photography on abandoned tracks. Therefore, many netizens have found that many train tracks are rusty. So why use these rusty tracks instead of stainless steel?

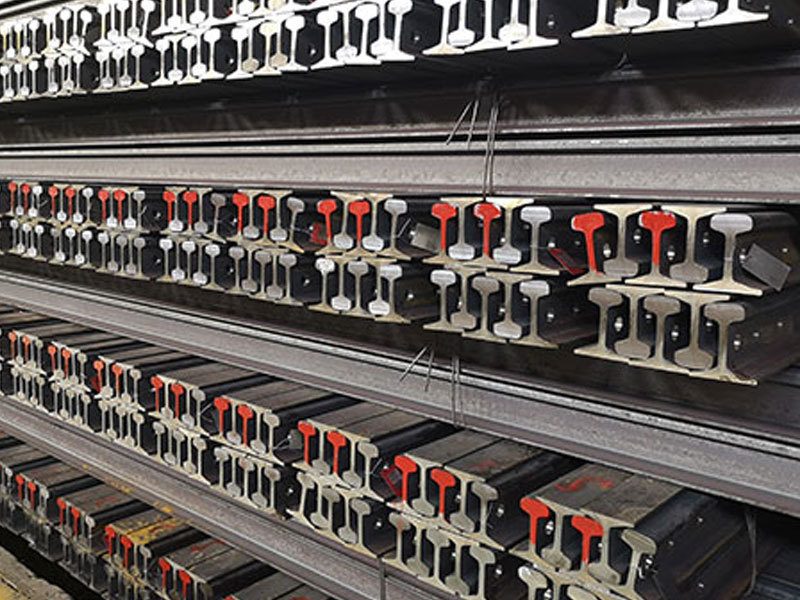

One major reason is that train tracks are usually outdoors, and the materials currently used for tracks in our country are high in manganese and carbon elements, known as high manganese steel. The reason for using this material is that it is very wear-resistant and can withstand various natural factors that challenge outdoor rails. Since wear is one of the most critical factors to pay attention to in tracks, deformation is also a factor that cannot be ignored. Various materials have their pros and cons. Therefore, when comparing the pros and cons of various aspects, it is best to use materials like the ones we have now. Lifting rail

The reason for not choosing stainless steel is actually quite simple: train tracks suffer from wear and deformation over the years. This is very fatal for train tracks. Although the cost of high manganese steel is somewhat cheaper than stainless steel, the costs of laying, construction, and later maintenance are also very high. Although the price of high quality must also be high, compared to the safety of the people across the country, this is a small matter. Lifting rail

Secondly, wear, deformation, and rust are easier to repair and handle. The railway department has a specialized job called flaw detection. The staff in this department must check the railway they are responsible for every day on the same route, conducting inspections and investigating damages. They immediately report any non-compliant areas for repair. This job is also very hard; regardless of whether it is windy or rainy, they must protect their workplace, and the work content is very boring, doing the same work every day without any novelty. Therefore, a strong sense of responsibility is also necessary to complete this job.

From the above introduction, we have learned about some maintenance of rails. Well, the lifting rail manufacturer will not elaborate further today. If you have any questions, you can leave a message for us or consult our customer service staff. Our company has various light rails, lifting rails, and tracks. We welcome everyone to choose!

Tag:

Previous Page

recommend News

Saint Ark explains what light rail is.