How to check the quality of used lifting rails?

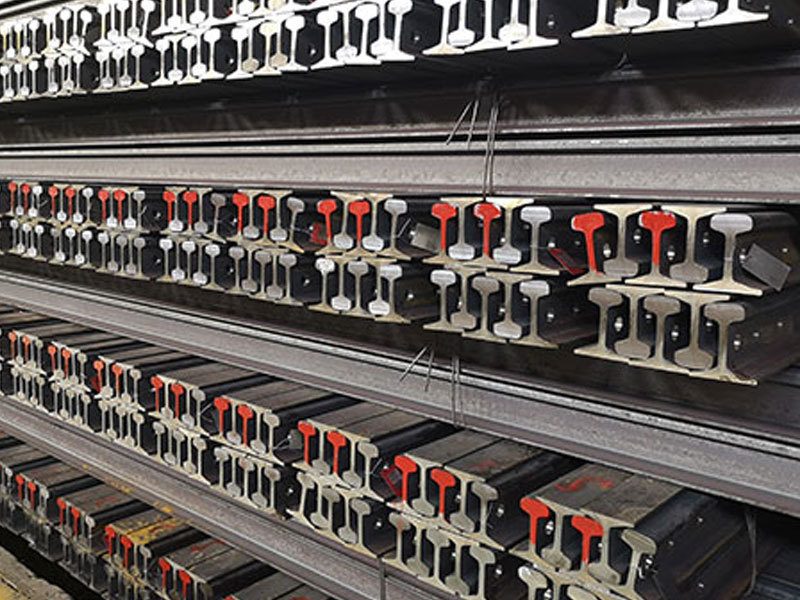

There is a unique product called "reused rails." Simply put, reused rails are products that involve the re-utilization of old rails—reprocessing previously damaged rails without delaying normal use. The application fields of reused rails are numerous; in addition to being used for laying tracks for train transportation, they can also be used in areas with special requirements such as heavy truck transportation and lifting platforms.

However, effective inspection work must be carried out for the secondary utilization of replaced rails, and they can only be used after meeting standards. What aspects need to be inspected? The inspection of reused rails has special standards, and they can only be used if there are no defects. Today, the Zhongxiang Rail Technology team summarizes the following aspects for everyone, hoping that you will have a clear understanding of this product, so that you can ensure opportunities when purchasing and using it!

1. The welding surface of the rail should have a smooth, fine scale appearance, with no grooves, continuous, no wrinkles on the surface, and a gentle metal connection. The welding effect should be seamless, allowing only a few surface pores. Within the range of 3 meters of welding, the pin clamp should not be tightened, so that the rail can be extended during welding.

2. The specific specifications of the welding should be checked to see if they meet technical standards, and whether there are defects, pores, burn-through, weld spatter, gaps, and unfilled grooves, etc. If any defects are found, repairs should be made, and they can only be used after meeting the standards.

3. Place the rail on a steel pad, carefully calibrate it to the correct center position, and after calibration, immediately tighten the pin clamp.

China has very high reliability requirements for the processing of rails. Although the replaced rails are not brand new, they actually only have slight damage, and re-utilization is clean and harmless, which can also save energy and economic costs. However, everyone must remember that when reused rails are damaged to the following levels, they can no longer be used:

1. The depth of the guard rail spacer marks exceeds or is equal to 4mm and cannot be reused.

2. The depth of the scratches on the rail surface exceeds or is equal to 2mm and cannot be reused.

3. The depth of the detached block is greater than or equal to 3mm, and the length is greater than or equal to 15mm and cannot be reused.

4. The depth of the detached block is greater than or equal to 3mm, and the length is greater than or equal to 15mm and cannot be reused.

5. Rails with vertical wear greater than or equal to 8mm and lateral wear greater than or equal to 12mm cannot be reused.

Tag:

Previous Page

Previous Page:

recommend News

Saint Ark explains what light rail is.