The difference between miner steel and I-beam steel lies in their shapes and applications. 1. **Shape**: - Miner steel typically refers to a type of steel used in mining applications, which may have various shapes depending on its specific use. - I-beam steel, on the other hand, has a distinct I-shaped cross-section, which provides high strength and stability. 2. **Applications**: - Miner steel is often used in the construction of mining equipment and structures, where durability and resistance to harsh conditions are essential. - I-beam steel is commonly used in building construction, bridges, and other structural applications due to its ability to support heavy loads. 3. **Manufacturing Process**: - The production processes for these two types of steel may also differ, with I-beams typically being rolled from steel billets, while miner steel may be produced in various forms depending on its intended use.

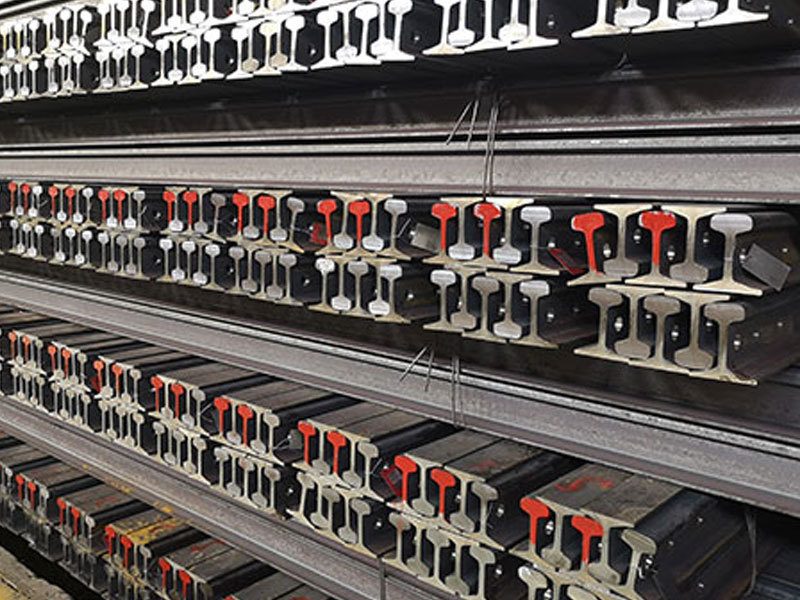

To discuss the difference between mining steel and I-beam steel, we first need to clarify one question: what is mining steel and what is I-beam steel? Understanding these conceptual issues will help us identify the differences, right? So, let's first talk about mining steel. What is mining steel? Mining steel, fully known as mining I-beam steel, is suitable for roadway support in mines. And what about I-beam steel? I-beam steel, also known as steel beams, is a long strip of steel with a cross-section in the shape of an I. I-beam steel is divided into ordinary I-beam steel and lightweight I-beam steel. It is a type of steel with a cross-section shaped like an I.

Now that we have clarified the conceptual issues, let's talk about the characteristics of mining steel. The main characteristics of mining steel are stable performance, reasonable structure, and both strength and stiffness are just right. Due to the characteristics of mining steel, such as light weight, small cross-sectional weight, complex deformation, many rolling passes, rapid temperature drop of rolled pieces, and difficulty in falling off the groove, it can be said that the design and development difficulty is very high from a development perspective. Mining steel is mainly used for roadway support in coal mines. Now let's talk about the characteristics of I-beam steel, whether it is ordinary I-beam steel or lightweight I-beam steel.

Due to the relatively high and narrow cross-sectional dimensions, the inertia moments of the two main axes of the cross-section differ significantly, so it can only be used directly for components that are bent in the plane of its web or for constructing truss-like load-bearing components. It is not suitable for axially compressed components or components that are bent perpendicular to the web plane, which greatly limits its application range. I-beam steel is widely used in buildings or other metal structures.

What is the difference in specifications between mining steel and I-beam steel?

Specifications for I-beam steel: specifications range from 10# to 63#.

Specifications for mining steel: specifications range from 9# to 12#.

What is the difference in material between mining steel and I-beam steel?

Material of I-beam steel: mostly Q235 material.

Material of mining steel: 20MNk Q275 material.

What is the difference in usage between mining steel and I-beam steel?

Usage of I-beam steel: commonly used in steel structures, support, bridges, and simple supports.

Usage of mining steel: used for coal mine support steel structures, in places requiring strong support.

Mining steel, arch-shaped collapsible support, pressure testing, is often used in roadways excavated under conditions of soft rock, fractured zones, and severe dynamic pressure effects, where metal collapsible supports are commonly employed.

(1) The original support form does not meet the surrounding rock pressure requirements, and the support cross-section parameters are unreasonable.

(2) The cost of U-shaped steel supports is too high, and the processing of support components is difficult.

(3) It is necessary to make full use of existing mining steel to develop a collapsible support that has a simple structure, reasonable cross-section parameters, good mechanical properties, and meets the requirements of the mine.

Tag:

Previous Page

recommend News

Saint Ark explains what light rail is.