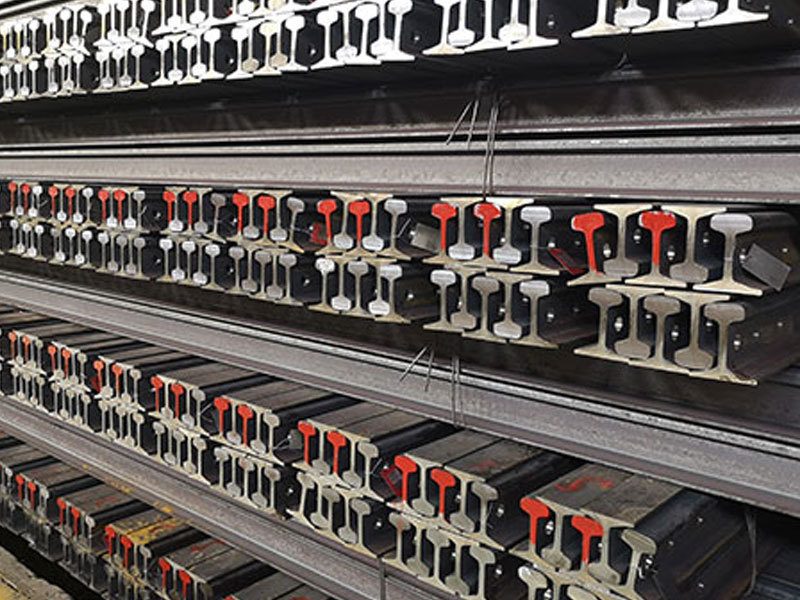

The differences between domestic and imported lifting rails.

With the continuous advancement of science and technology, various industries have also made great progress, regardingcrane railits development prospects are also quite good, so the demand is constantly increasing, and there are also many manufacturers on the market. As a manufacturer, we are here to share knowledge about crane rails, let's take a look!

Crane rail is a type of mechanical equipment, widely used in various fields such as manufacturing, industry, transportation, etc. It can horizontally move large materials and vertically lift them through a combination of multiple actions within a certain range. During operation, it completes the loading, unloading, transfer, and installation of goods through two types of actions.

Next, let's compare the differences between domestic and imported crane rails.

1. Tensile strength: Domestic rails generally stabilize at a maximum of 690MPa, while imported rails can reach up to 1080MPa. The commonly used strength is around 880MPa.

2. Surface hardness of the rail: Domestic 880MPA, which is generally referred to as 90 kg level, has a hardness of about 220HB, while the same level of imported rails generally guarantees a minimum hardness value of 260HB. The main reason for the gap is that foreign large manufacturers use long processes, controlling the key steps of composition, namely steelmaking; while domestic manufacturers generally use short process rolling mills, sourcing their raw materials—steel billets—from different domestic factories, leading to unstable chemical composition of the billets.

3. Service life: The low strength of domestic rails results in weak load capacity, significantly reducing their lifespan and stability. Imported rails, due to full-process control over raw materials, ironmaking, steelmaking, and rolling, thus have a longer lifespan and stability.

4. Overall cost: On the surface, domestic materials appear cheaper, but considering their shorter lifespan and overall costs, imported materials are relatively more cost-effective.

Therefore, in major projects, our country basically uses imported rails, as their longer lifespan not only ensures the long-term stable operation of the projects but also reduces overall maintenance costs.

Tag:

Previous Page

recommend News

Saint Ark explains what light rail is.