Lifting Equipment Hoisting Track Classification, Installation, and Usage Specifications

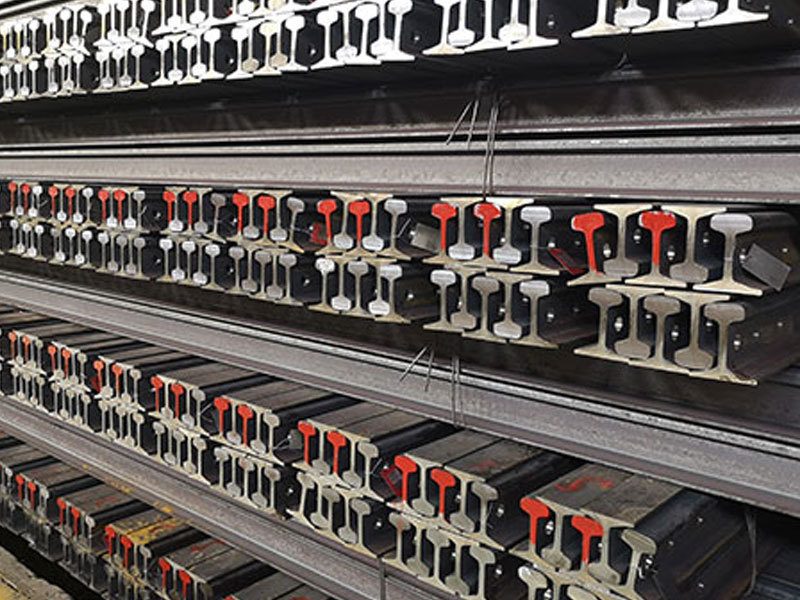

According to the use and type of lifting equipment, lifting equipmentLifting railThere are special rails, railway tracks, straight optical axes, and P-type rails. Compared to general railway steel rails, the top of the lifting equipment's special steel rail is wider, has a relatively small height, and a thick web, which helps improve the contact situation with the wheels and is beneficial for bearing horizontal loads. However, the price is relatively high, so in most cases, the more important option is the P-type rail.

The lifting equipment that operates on the ground mainly uses railway steel rails; gantry cranes use special steel rails but can also use other rails. The tracks for lifting hoist cars have a similar form, fixed to the cable tray or horizontal telescopic arm of the lifting equipment, and the flange plates of the I-beam can serve as the tracks for the cars. The prerequisites for lifting equipment tracks include concrete, reinforced concrete, and metal beams, with various conditions that should be selected based on actual situations and on-site operations.

Installation and usage specifications for lifting equipment tracks:

The joints of the lifting equipment tracks must ensure orderly advancement during operation and reduce impact. The verticality of the track line, guard rails, and the height difference between the two rail surfaces have a significant impact on the operational characteristics of the lifting equipment, and assembly must be carried out according to the precision of the standards. The rails should be firmly fixed to prevent rolling along the base. During use, the tracks may deform, and the tops of the rails are prone to damage, so it is advisable to use removable structures such as anchor bolts between the tracks and the foundation for easy adjustment and replacement.

1. Safety inspection of the lifting rail: Check for cracks, looseness, or corrosion in the tracks, anchor bolts, and straight clamps. If cracks are found, they should be replaced regularly; if there are other defects, they need to be repaired promptly. The main inspection tool is the track flaw detection equipment.

2. Measurement and adjustment of the lifting rail:

(1) The parallelism of the lifting rail can be checked using a stainless steel wire method. A 0.5mm stainless steel wire is pulled up on both sides of the track, and then measured step by step using a plumb line, with a measurement point spacing of about 2m.

(2) The design elevation of the lifting rail can be accurately measured using a level.

(3) The span of the lifting rail can be checked using a tape measure or an infrared measuring instrument. The allowable error for the gantry crane guard rail is ±5mm; the vertical slope of the track is 1/1500. The allowable error for the relative height of the two tracks is 10mm.

(4) The joints of the lifting rail can be made as direct joints or as 45° angled joints. Angled joints allow the wheels to advance orderly at the interface, with a general joint gap of 1-2mm. In cold regions, attention should be paid to the impact of environmental temperature on the gap, generally 4-6mm. The height difference between the two tracks at the interface should not exceed 1mm.

Tag:

recommend News

Saint Ark explains what light rail is.