Common Issues in Assembling Single Girder Bridge Crane Track

In recent years, with the development of the social economy, single beamlifting railprocessing industry has made significant progress, and the industries using single beam bridge cranes are increasing. Moreover, most indoor spaces are not compatible with large and medium-sized single beam bridge cranes, so such working environments require the emergence of new products with combat skills or structures for single beam bridge cranes.

In our country, the single beam lifting machinery manufacturing industry is developing rapidly, with continuous growth in industrial output value. Along with the further expansion of the offline promotion market, the trend of moving towards the mobile internet e-commerce market has become an inevitable trend for industrial development. As mobile e-commerce increasingly impacts traditional manufacturing and the offline market becomes saturated, the single beam lifting machinery manufacturing industry is gradually stepping onto the path of mobile e-commerce development.

Common issues in the assembly of single beam bridge crane lifting rails:

The quality of the assembly of the lifting rails of single beam bridge cranes directly determines the operational characteristics of the cranes. To ensure the quality of the lifting rail installation, it is necessary to strictly follow the corresponding national standards during the assembly of the lifting rails of single beam bridge cranes. Below is a brief overview of the quality management regulations for the assembly of single beam bridge crane tracks.

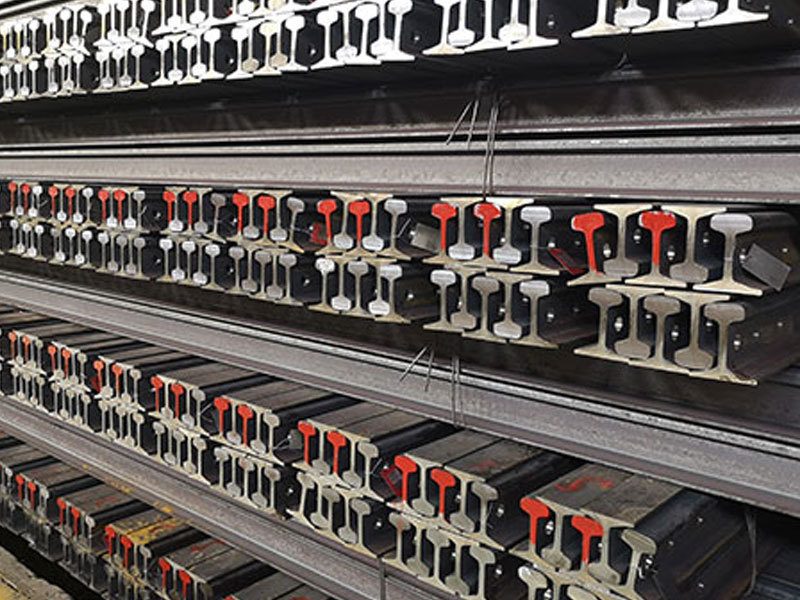

The types of operating tracks for single beam bridge cranes can be divided into single beam bridge crane rails, railway steel rails, and square steel pipes. Among them, the top shape of the rail is protruding, and the bottom is flat, which can increase the contact area with the foundation and reduce the pressure on the utilization coefficient. Generally, the cross-section of the rail is I-shaped, which can enhance the tensile strength of the rail. Square steel pipes cause significant wear on the wheels and are commonly found in single beam bridge cranes with lower lifting heights and slower starting speeds. The commonly used material for square steel pipes is Q275, while the rail material for single beam bridge cranes is often made of U71Mn. In places with high requirements for tracks, to improve the wear resistance and corrosion resistance of the tracks, tracks made of classic high-alloy steels with added Mn, Si, P, etc., can be used.

The common installation steps for single beam bridge crane lifting rails include: pin fixing method, hook-shaped screw rod fixing, and the combined fixing of anchor bolts, etc. There are two types of beams used for track installation, namely steel structure beams and precast concrete beams. Among them, precast concrete beams should be made with reserved holes for the installation of anchor bolts during the installation process.

The holes in the track pins are generally shaped holes, which facilitate adjustments in the horizontal direction during track assembly. If adjustments are needed in the vertical direction, pads can be added at the bottom of the rails. The production of track pins should ensure that their rigidity meets operational requirements. Depending on the load-bearing capacity, lifting rail pins can be made into double-hole or two-hole pins.

Whether the installation of the lifting rails of single beam bridge cranes is good directly affects the operational quality of the cranes. Therefore, the quality management of the assembly of single beam bridge crane lifting rails is quite strict. During the installation process, it should still be carried out according to national standards and engineering drawings to ensure normal and safe operation.

Tag:

recommend News

Saint Ark explains what light rail is.